American Made, Iron Clad Protected - Discover the Industries Best Warranty.

Blog

5 Benefits of Welding Screens

Welding areas can be unsafe environments without proper protections in place. To keep employees and those who frequent the facility where welding operations take place safe, facility owners may utilize welding curtains. Welding curtains can create customized spaces designated specifically for welding operations.

They can also reduce noise levels throughout the building, contain high temperatures from welding flames to one space, keep welding fumes from spreading and, ultimately, keep welders safe from harm. Want to know more about how you can use welding screens to enhance your welding operations?

Examine our list of benefits.

Creates Welding Section

To begin creating a safe space for welding, many facility owners need to section off a designated area. Permanent walls may not be ideal, as they are expensive to build and do not provide flexibility.

Welding screens, however, provide easy access and can be rearranged as needed. If you need to cover larger cell or area, a custom welding curtain partition may be the ticket to fit the spaces throughout your facility.

Reduces Noise

Welding produces noises levels that can be damaging to both welders and those in the building where welding activity takes places. Welders often even wear earplugs to protect their hearing from the loud sounds of metal grinding.

The noise produced from welding areas can ultimately become a distraction to employees working in other sections of the building. When properly positioned, sound shield welding screens can create a barrier from the rest of the building to contain the noise produced.

Controls Temperatures

Welding produces high temperature levels that could be dangerous. While welders wear the appropriate clothing to protect themselves from the heat welding produces, other employees walking around the facility may not.

Welding can produce flame heats up to 6,300 degrees Fahrenheit, which could put those around the area at great risk. Welding screens are composed of materials to create a superior barrier that can withstand extreme heat and abuse. These screens help reduce any risks associated with heat levels, keeping everyone in the building safe from harm.

Contains Welding Fumes

Welding produces chemicals and fumes that could be potentially harmful. While welders wear masks to protect themselves from these fumes, other employees in the building most likely do not.

If the gases and fumes produced from the welding process were not contained, they could be detrimental to others. Welding safety curtain and screen products create an enclosure that combined with other protective measures like ventilation, cooling fans and respirators, keep everyone in the environment safe from harm.

Keeps Welders Safe

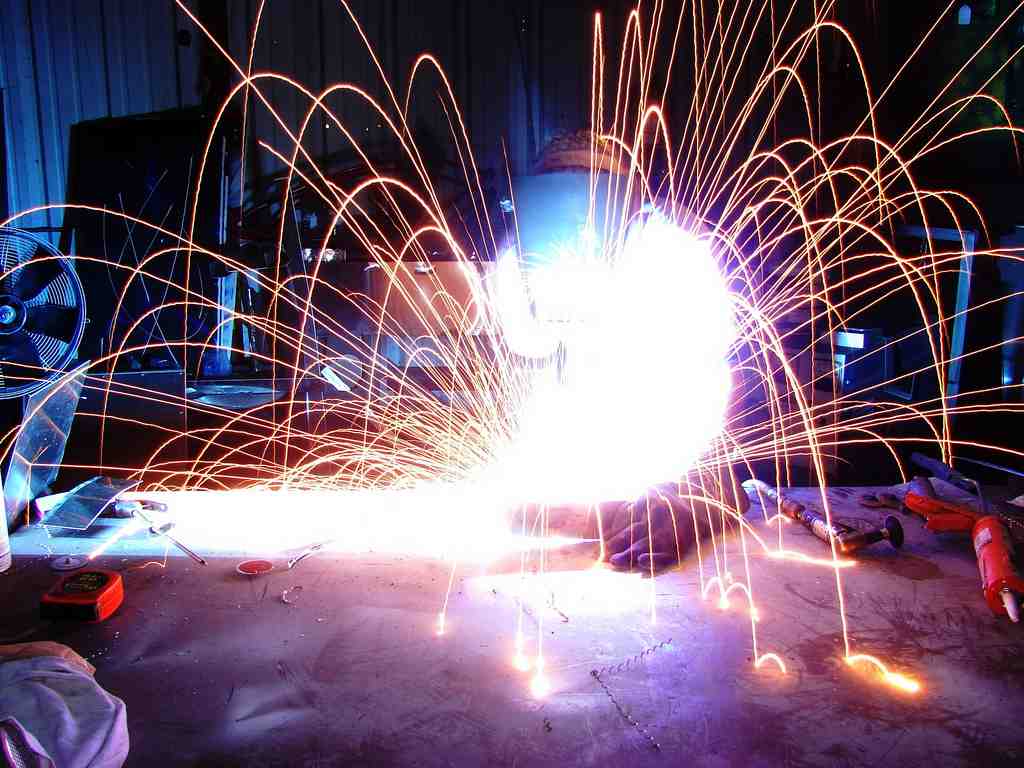

Without the right protections, the welding process can be dangerous as it produces sparks of UV light that could burn or blind employees. In addition to welding gear, facility owners must set up welding screens.

These flame-resistant screens protect welders and others in the facility from any flashes or other debris. Because welding screens are composed of heavy-duty materials, you can trust that they will withstand high heats and keep those in your building free of harm.

Want to know more about the advantages of welding screens? Contact a Steel Guard representative today.

Recent Posts

- Porch Curtains: 8 Amazing Reasons to Install These Curtains in Your Home

- Chemical Splash Curtains and Their Applications in Different Industries

- Outdoor Sound Curtains for Farms and Animals

- Construction Sound Barriers: Why Every Construction Site Should Have These?

- Industrial Blackout Curtains and Their Applications in Different Settings

- Sound Curtains for Industrial Use: How to Buy the Right One

- Noisiest Cities in the US

- Warehouse Cooling – 10 Ways to Upgrade Without AC

- How to Prepare your Construction Site for Winter – 7 Useful Products

- Clear Vinyl Tarps: Where are the Useful Tarps Used

Categories

- Accordion Fold Curtains

- Agri-Shield Curtains

- Auto Body Shop Curtains

- Bio Plastics

- Industrial Divider Curtains

- Industrial Safety Products

- Insulated Curtain Walls

- Machine Guard Safety Fencing

- Mesh Curtain Screens

- Outdoor Curtains

- PVC Strip Curtains

- Soundproof Noise Blocking Curtains

- Spray Paint Booth Curtains

- Tarps

- Thermal Curtains & Covers

- Uncategorized

- Warehouse Dividers

- Welding Blankets

- Welding Curtains

- Welding Screens