American Made, Iron Clad Protected - Discover the Industries Best Warranty.

Blog

How to Contain Warehouse Welding Fumes with Welding Curtains

How to Contain and Control Welding Fumes in a Warehouse

In many welding applications, the process can produce harmful fumes that can cause potential health issues for employees or even damage equipment over time. Because of the hazard that fumes present in many welding processes, facilities should utilize state-of-the-art fume control equipment.

Proper Ventilation

The biggest thing to have in place is proper ventilation. This can happen in three ways. There is natural dilution ventilation, having a large enough space to let the fumes dissipate. That means opening windows and doors to let as much fresh air in. This is the least effective strategy and should only be used if welding infrequently. That is because it is a slow process, and there is little control over how the air gets cleared.

There is mechanical dilution ventilation. That would be having fans close to the welder or in the building to circulate the air around. A lot of movement of air is needed to be sure that the contaminants are being eliminated.

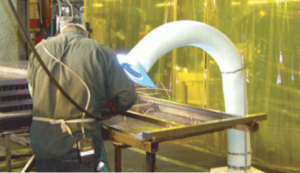

Local exhaust ventilation is the best solution (See the picture to the right) These ventilation systems are portable and relatively inexpensive and should last for many years. The only maintenance should be a once in a while replacement of the filters. A good place to find and purchase them is a place like McMaster Carr . The closer you can get to the source of the fumes, the faster you can remove them. You are eliminating exposure, even in small doses. This is also the most expensive option as a dedicated exhaust has to be in place to move the contaminated air in an isolated system.

PPE Welding Gear and Barriers Also Help Ventilation and Breathability

While certain fume collection machinery is ideal for these applications, facilities can also use a variety of welding barrier curtains, screens, and blankets to contain these dangerous fumes. Isolating which parts of the facility are contaminated by the fumes allows bystanders to stay healthy, and exhaust systems to focus on smaller areas. On top of that, having a good welding hood, can keep away harmful fumes from getting inhaled.

Welding Cells

Welding Cells

Welding and grinding cells can make it easy to isolate welding areas by setting up free-standing frames and cells. The materials used can block welding arc, sparks, and flash burn, while also helping contain fumes and chemicals within the work area. Bystanders are protected from every possible harm of the process. The availability of steel scrim for these cells also ensures long-lasting durability even in close proximity to the work.

Welding Curtains

Welding Curtains

Another way to block off work areas and contain potentially harmful fumes is through the use of welding curtains. Like welding cells, they can effectively protect staff and other nearby equipment from dangerous fumes, welding arc, flash burn, and sparks. The physical barrier keeps workers on the other side free to go about their work without worrying about harm. These curtains are often tinted to absorb all of the harmful UV radiation that can cause severe problems to eyes and skin. You can use them to block off larger workspaces such as entire sections of warehouses, or you can have smaller systems to separate smaller welding areas.

Welding Screens

Welding Screens

Welding screens are a sturdy option that can effectively protect your employees from welding hazards. They are designed to protect against MIG, TIG, grinding, plasma cutting, and other welding process hazards. Their design makes them difficult to break, with a galvanized square tube frame that helps make sure they hold up in many environments.

These curtains are more ideal for applications that need quick and smaller levels of protection, such as temporary welding areas with minimal equipment. As fast as these setups are to deploy, there is little excuse to avoid using them.

PVC Weld Strip Curtains

Unlike other welding curtains, PVC weld strips allow safe passage to adjoining areas while providing sufficient protection. If employees need to frequently enter and leave the welding space, these strips can enclose an entire area while allowing staff to pass through without resulting in uncontained hazards at any point. Their high-grade PVC materials can also, make sure that no curling occurs with these products over time, helping these curtains last for many years in a wide variety of applications.

Get Welding Curtains at Steel Guard Safety

At Steel Guard Safety, you’ll be able to get top-quality reliable welding curtains and many other types of curtain wall products that are useful in a variety of facilities. You can use a combination of any of these welding curtains in your facility to provide maximum protection for employees and equipment from harmful fumes. We’ll help you design a complete custom curtain system that keeps your facility safe at all times.

If you would like to get started on the design and implementation of any of our welding curtain products, or other curtain wall systems, contact Steel Guard Safety today for immediate assistance.

In many welding applications, the process can produce harmful fumes that can cause potential health issues for employees or even damage equipment over time. Because of the hazard that fumes present in many welding processes, facilities should utilize state-of-the-art fume control equipment. While certain fume collection machinery is ideal for these applications, facilities can also use a variety of welding barrier curtains, screens, and blankets to contain these dangerous fumes.

Recent Posts

- 7 Powerful Ways Industrial Curtain Walls Boost Employee Productivity

- Noise Enclosures vs. Traditional Soundproofing: Which Is Right for Your Facility?

- Steel Guard Safety Achieves SBA HUBZone Certification, Expanding Government Market Opportunities

- 5 Myths and 5 Truths about Smoke Curtains

- 7 Common Mistakes to Avoid When Setting Up Machine Guarding Fences

- Industrial Curtain Walls: 6 Reasons Why Manufacturing Facilities Must Have Them

- Industrial Soundproof Curtains: How to Decide Between Floor-Mounted and Ceiling-Mounted Curtains

- How to Transform a Noisy Open-Plan Office with Acoustic Baffles

- A Guide to Choosing the Best Concrete Blanket for Construction Projects

- Porch Curtains: 8 Amazing Reasons to Install These Curtains in Your Home

Categories

- Accordion Fold Curtains

- Acoustic Baffles

- Agri-Shield Curtains

- Auto Body Shop Curtains

- Bio Plastics

- Industrial Divider Curtains

- Industrial Safety Products

- Insulated Curtain Walls

- Machine Guard Safety Fencing

- Mesh Curtain Screens

- News

- Outdoor Curtains

- PVC Strip Curtains

- Smoke & Draft Curtains

- Soundproof Noise Blocking Curtains

- Spray Paint Booth Curtains

- Tarps

- Thermal Curtains & Covers

- Uncategorized

- Warehouse Dividers

- Welding Blankets

- Welding Curtains

- Welding Screens