American Made, Iron Clad Protected - Discover the Industries Best Warranty.

Blog

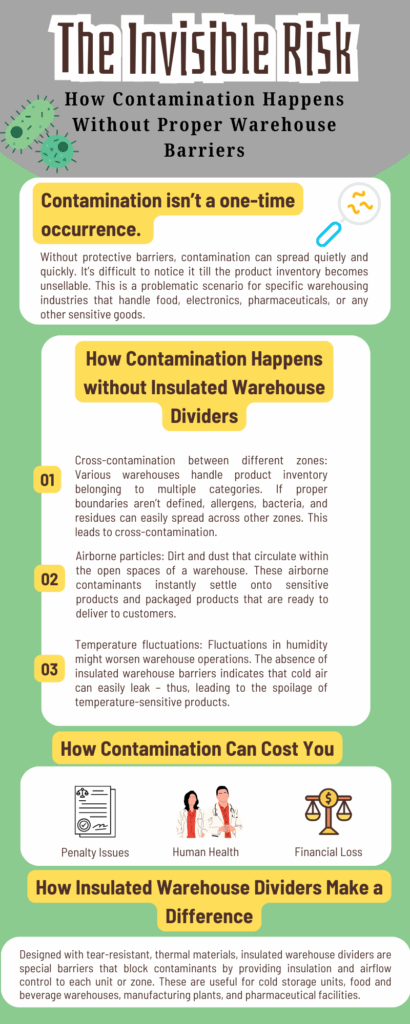

The Invisible Risk: How Contamination Happens Without Proper Warehouse Barriers

How Contamination Happens Without Warehouse Curtain Dividers

In warehousing, it’s easier to identify most of the operational risks (such as faulty equipment, damaged pallets, or unmarked aisles). But contamination is one of those risks that’s often invisible. Here’s another bitter truth: contamination within warehouses not only causes inventory damage but also leads to foodborne illnesses and contract cancellations – ultimately affecting business reputation.

Contamination isn’t a one-time occurrence. Dust particles frequently traveling from one warehouse unit to another, temperature changes causing product spoilage, and cross-contamination between finished and raw goods might often lead to compliance violations and unbearable financial losses.

Without protective barriers, contamination can spread quietly and quickly. It’s difficult to notice it till the product inventory becomes unsellable. This is a problematic scenario for specific warehousing industries that handle food, electronics, pharmaceuticals, or any other sensitive goods. However, there’s a practical solution to prevent contamination: insulated warehouse dividers.

Besides separating warehouse zones, insulated warehouse dividers are specifically designed to block contaminants and regulate temperatures. These barriers act as safety guards that protect perishable goods from spoilage.

But what happens if a warehouse runs without this protective shield?

In this post, we’ll highlight several ways in which contamination might happen if proper warehouse barriers are not installed. We’ll also explain how to prevent this invisible risk to achieve optimum warehouse efficiency.

Understanding How Contamination Happens without Insulated Warehouse Dividers

There’s nothing you can do once the inventory has been damaged due to contamination. Therefore, it’s wise to understand how and why these invisible allergens and bacteria develop. Once you know the root cause, you can prevent these unseen invaders from ruining your valuable inventory right from the beginning.

Let’s explore the root cause of contamination in detail so you can avoid costly issues:

Cross-contamination between different zones

Various warehouses handle product inventory belonging to multiple categories (including sensitive items, finished products, raw materials, and even hazardous chemicals). If proper boundaries aren’t defined, allergens, bacteria, and residues can easily spread across other zones. This leads to cross-contamination.

A food storage warehouse might face a cross-contamination issue if it handles raw food alongside ready-made, packaged food items without insulated barriers. Bacteria from raw food can easily travel to ready-to-eat food – thus, making these unsafe for customers. Such warehousing practice also doesn’t comply with food safety standards. It might also lead to failed inspections.

Industrial environments that lack physical dividers are also prone to similar triggers. Fumes from paints, solvents, or lubricants may penetrate into packaging areas. This can directly contaminate clean products.

In both these situations, separating each zone with insulated warehouse dividers directly eliminates the risk of cross-contamination.

Airborne particles

It’s challenging for warehouses to operate in flawless conditions. Continuous movement from workers, forklifts, and trucks stirs up dirt and dust that circulate within the open spaces of a warehouse. Besides dust particles, pollen and fumes are also the hidden culprits that can easily enter the warehouse. These airborne contaminants don’t disappear. They instantly settle onto sensitive products and packaged products that are ready to deliver to customers.

For pharmaceutical or food distribution industries, airborne particles pose an invisible risk. Even a little dust might weaken business claims about maintaining sanitation standards. Besides, chemical fumes can directly compromise the quality of medical supplies. The worst part is that dust and dirt often go unnoticed till the finished goods reach the customer. This results in rejected shipments and frequent returns.

Sellable products stored in a well-maintained and clean warehouse can also attract airborne particles if insulated warehouse dividers aren’t installed.

Temperature fluctuations

Physical particles aren’t the only contaminants present in a warehouse. Sometimes, fluctuations in humidity might worsen warehouse operations. Frozen foods and pharmaceutical products have a high sensitivity ratio if they are exposed to a slight temperature change. The absence of insulated warehouse barriers indicates that cold air can easily leak – thus, leading to the spoilage of temperature-sensitive products. Plus, humidity in storage zones can affect product quality.

Such temperature fluctuations lead to multiple issues: mold growth on pallets, degraded potency of medicines, spoiled food, and condensation on packaged products. Condensation further allows bacteria and mold to grow quickly. The ripple effect can be seen when cardboard packaging begins to weaken and labels start peeling off. As a result, finished products lose their market value due to the deterioration of the outer packaging.

Is Contamination Risk Something Serious?

It’s not worth ignoring even the minute signs of contamination. Negligence in installing warehouse barriers within open spaces can cost a business in different ways:

Penalty issues

Regulatory bodies, including OSHA, USDA, and FDA, require warehouse managers to implement sanitation and safety practices according to their strict standards. Therefore, non-compliance in terms of using inadequate warehouse barriers indicates the possibility of legal action and hefty fines. It’s specially applicable to the food storage and pharmaceutical industries.

Financial loss

Spoiled products, product returns, and rejected shipments cost businesses millions annually. Even if contamination is detected once, the entire consignment can go to waste. Consequently, it damages customer relationships and breaks a brand’s credibility.

Safety concerns

Contaminated work zones also put a strain on workers’ health. Fumes, dust, and debris trigger respiratory issues, thereby leading to absenteeism and low productivity. In the long run, workers’ consistent exposure to allergens increases business costs and decreases business profits.

How Insulated Warehouse Dividers Make a Difference

By separating one warehouse unit from the other, physical barriers are able to maintain temperatures while controlling dust. However, they are not a permanent solution for businesses that store and sell contamination-sensitive products. The objective is to ensure that each work zone has been insulated well. This helps avoid contamination. That’s when insulated warehouse dividers do the job.

Designed with tear-resistant, thermal materials, insulated warehouse curtain dividers are special barriers that block contaminants by providing insulation and airflow control to each unit or zone. These heavy-duty dividers are useful across the following industries:

- Cold storage units: keep chilled and frozen products at consistent temperatures

- Food and beverage warehouses: prevent allergens, spoilage, and bacteria in perishable products

- Manufacturing plants: control pollutants by separating production processes

- Pharmaceutical facilities: meet regulatory compliance by maintaining sterile environments

What to Know Before Choosing the Right Insulated Warehouse Divider

It’s not just about separating one unit from the other. It’s about achieving safety while managing operating costs. So, it’s important to consider several factors before choosing an insulated warehouse divider:

Temperature control requirements

Evaluate the level of insulation your facility requires. If you’re handling temperature-sensitive products, you should choose dividers with a high R-value and high thermal resistance.

Safety and compliance standards

Overlooking safety standards might lead to costly fines. To avoid this problem, select dividers that comply with hygiene requirements, fire ratings, and smoke control regulations.

Durability

Insulated dividers are exposed to heavy use. Therefore, it’s essential to choose the ones made with vinyl-coated material, corrosion-resistant hardware, and reinforced stitching. Also, inquire if these dividers also come with warranty coverage.

Flexibility

Warehouse layouts may often change. So, it’s wise to choose insulated warehouse dividers that are modular, easy to reconfigure, and can quickly be relocated.

The Takeaway

Contamination inside industrial settings can be an invisible enemy for any company dealing with the storage of perishable and sensitive goods. Failed inspections, spoiled goods, and customer complaints can lead to a loss of revenue. It can also result in business shutdowns. However, insulated warehouse dividers provide an effective solution to combat contamination.

Whether your business handles pharmaceuticals, food, electronics, or industrial equipment, installing insulated warehouse dividers will help manage your facility safely and efficiently. However, the trick is to select the ones that fulfill the insulation needs of your storage facilities. Before investing in an insulated warehouse divider, identify your business requirements and choose the one that offers a higher R-value, strong durability, and quick and easy maintenance.

Recent Posts

- The Silent Safety Hero: Why Fixed Draft Curtains Are Required in High-Rack Storage Facilities

- The Invisible Risk: How Contamination Happens Without Proper Warehouse Barriers

- Are Your Insulated Warehouse Curtains Compliant

- Understanding Noise Regulations – When Is a Temporary Noise Barrier Legally Required?

- 7 Powerful Ways Industrial Curtain Walls Boost Employee Productivity

- Noise Enclosures vs. Traditional Soundproofing: Which Is Right for Your Facility?

- Steel Guard Safety Achieves SBA HUBZone Certification, Expanding Government Market Opportunities

- 5 Myths and 5 Truths about Smoke Curtains

- 7 Common Mistakes to Avoid When Setting Up Machine Guarding Fences

- Industrial Curtain Walls: 6 Reasons Why Manufacturing Facilities Must Have Them

Categories

- Accordion Fold Curtains

- Acoustic Baffles

- Agri-Shield Curtains

- Auto Body Shop Curtains

- Bio Plastics

- Draft & Smoke Curtains

- Industrial Divider Curtains

- Industrial Safety Products

- Insulated Curtain Walls

- Machine Guard Safety Fencing

- Mesh Curtain Screens

- News

- Outdoor Curtains

- PVC Strip Curtains

- Smoke & Draft Curtains

- Soundproof Noise Blocking Curtains

- Spray Paint Booth Curtains

- Tarps

- Thermal Curtains & Covers

- Uncategorized

- Warehouse Dividers

- Welding Blankets

- Welding Curtains

- Welding Screens