American Made, Iron Clad Protected - Discover the Industries Best Warranty.

Blog

Are Your Insulated Warehouse Curtains Compliant

Are Your Insulated Warehouse Curtains Compliant? These Food Storage Regulations Say It All

Safety is a priority for warehouses that deal with food products. Due to high perishability, food warehouses must comply with certain standards to ensure the optimum quality of food products. If you’re one of those responsible warehouse managers who use insulated warehouse curtains, you are possibly on the right track.

But here’s the concern: do these dividers also meet food storage regulations?

No matter how carefully you’re taking care of food safety, hygiene, and temperature, it’s important to know if your food storage strategies are up to the mark or not.

The only way to ensure that your insulated warehouse curtains are doing the right job is by knowing if they comply with specific food storage regulations. Digging deeper is worthwhile because failure to meet these regulations can have serious consequences (spoiled inventory, unsuccessful FDA audits, product recalls, fines, and even warehouse shutdowns).

The good news is that learning about food storage regulations, the authorities behind these regulations, and the proper use of insulated warehouse curtains can help you stay compliant in the food warehousing industry. In this post, we’ll discuss all of it in detail.

Food Storage Regulations (and the Authorities Behind These Regulations)

The network of federal, state, and local regulations governs food safety compliance. All these regulations have something in common: to minimize the risks of foodborne illnesses by preserving the quality and freshness of food products.

Whether you are managing a food distribution unit, a low-temperature warehouse, or a cold storage space, you must meet food storage regulations.

Let’s find out about the authorities and the regulations they enforce for achieving food safety.

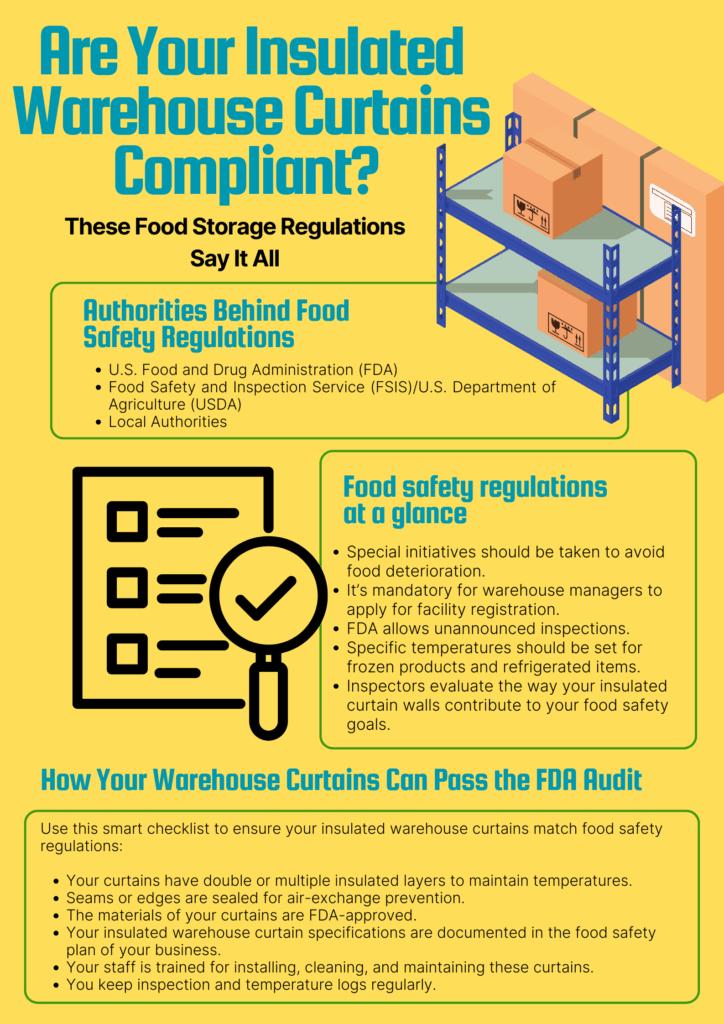

FDA

The U.S. Food and Drug Administration (FDA) takes practical measures to maintain the optimum safety of food products. It enforces the following regulations:

- Preventive controls should be implemented to avoid food contamination

- Facility materials and layout of warehouses should be insulated (to block allergen exposure)

- Special initiatives should be taken to avoid food deterioration

- It’s mandatory for warehouse managers to apply for facility registration

- FDA allows unannounced inspections

USDA and FSIS

If your business involves handling poultry, processed eggs, or meat, you should ensure that your warehouse complies with the standards of the Food Safety and Inspection Service (FSIS). FSIS is an agency that contributes its efforts in public health and safety by working under the U.S. Department of Agriculture (USDA). Besides providing tools to assess food safety, it enforces its standards in the following ways:

- Specific temperatures should be set for frozen products and refrigerated items.

- Temperatures should be continuously monitored.

- Initiatives should be taken for the prevention of microbial growth, moisture, and thermal drift.

- Warehouses must follow specific sanitization procedures to clean surfaces.

Local health authorities

Depending on the location of your warehouse, local authorities follow the Food Code set by the FDA. It’s particularly applicable for foodservice and retail warehousing. These authorities also impose inspection schedules, licensing, and other temperature control standards depending on your food storage category. Inspectors evaluate the following:

- The way your physical warehouse dividers or insulated curtain walls contribute to your food safety goals

- Your documentation

Are Your Insulated Warehouse Curtains Compliant?

The above-mentioned food storage regulations indicate the use of insulated warehouse curtains to prevent food spoilage that could possibly lead to foodborne illnesses. Also called insulated curtain walls, these warehouse dividers are designed with various materials (having variations in quality, depending on manufacturers). Therefore, warehouse managers should responsibly select the ones that meet the food storage regulations.

Fortunately, it’s easy to identify if your insulated curtain walls match the requirements of the regulatory authorities. Let’s have a deeper look at the regulations and how these special dividers fit in:

Temperature Control

The Food Safety Modernization Act (FSMA) requires food storage professionals to act proactively in documenting and managing temperature control. For frozen food products, the ideal temperature is 0°F or even below. For refrigerated food, the temperature range can be between 32°F and 40°F.

Since the handling of both frozen and refrigerated food items go through several areas (e.g., receiving, storing, staging, shipping, etc.), each area must maintain these temperature ranges. The usage of insulated warehouse curtains is applicable in each of these areas to prevent thermal intrusion. The goal is to ensure that there are no airflow breaches. So, your insulated curtains are compliant only if they are manufactured with multiple insulating layers while providing a higher R-value.

Zoning

A compliant food storage warehouse is one that focuses on preventing cross-contamination from pathogens, dust, pests, chemicals, and allergens. Insulated warehouse curtains contribute to zoning the warehouse by dividing each area from the other. However, these curtains can meet food storage regulations only if they are made from non-porous materials that are FDA-compliant. They should also be easy to sanitize.

While installing warehouse curtain walls, make sure these are installed with tight seals, bottom-edge barriers, and overlapping panels to prevent moisture or air.

Sanitization of surfaces

Auditors inspect how cleanable insulated warehouse curtains are. It’s essential to ensure that the surfaces of these curtains do not catch mold or bacterial growth. Therefore, FDA standards require warehouse managers to install insulated curtains that have smooth and washable surfaces. Besides, every surface of an insulated curtain should be moisture-resistant, mildew-inhibiting, and durable (even after several washes).

Audit readiness, SOPs, and documentation

When inspectors walk into your warehouse, showing your recently installed insulated dividers isn’t enough. They want you to give them some real proof. That’s when documentation comes in. FSMA requires food storage managers to have written SOPs (Standard Operating Procedures) to prove that all equipment related to food safety is regularly inspected and maintained.

Some of the documents every facility manager needs to have include inspection checklists, logs of employee training, temperature sensor records, corrective actions that had been taken for curtain failure, and routine maintenance checklists.

How to Prepare for an FDA Audit

Even a minor negligence can break your business reputation. It can even lead to major consequences (such as warning letters, facility suspensions, or even contract terminations). Therefore, its mandatory to ensure that your warehouse passes the FDA audit.

The following questions will help you evaluate your insulated warehouse curtains for compliance:

- Do the curtains have double or multiple insulated layers to maintain temperatures?

- Are the seams or edges sealed for air-exchange prevention?

- Are the materials of these insulated curtain walls FDA-approved?

- Are the warehouse curtain specifications documented in the food safety plan of your business?

- Is the staff trained in terms of installing, cleaning, and maintaining these curtains?

- Are inspection and temperature logs kept regularly?

If you answer, “yes” to all these questions, it indicates that your insulated warehouse curtains are compliant and will likely pass the FDA audit.

The Takeaway

Food storage is a critical concern. It becomes more challenging when your warehouse isn’t prepared for an FDA audit. Therefore, it’s wise to plan ahead, learn about food storage regulations, and implement the right strategies to comply with the strict regulations.

Installing insulated warehouse curtains is one of the crucial steps to stay compliant. However, what matters is the quality and durability of these special curtains. An effective way to ensure this is to choose the ones that are offered by a reputable company, provide a higher R-value, and prevent thermal bleed. Size is another crucial factor. If you have varying food storage requirements, it’s wise to go for customized sizing options.

Once you’ve successfully installed insulated warehouse curtains into your facility, it’s equally essential to maintain them for enhanced performance and longevity. Training workers for regular maintenance while routinely monitoring temperature controls will ensure that your insulated warehouse curtains stay compliant with food storage regulations.

Recent Posts

- The Silent Safety Hero: Why Fixed Draft Curtains Are Required in High-Rack Storage Facilities

- The Invisible Risk: How Contamination Happens Without Proper Warehouse Barriers

- Are Your Insulated Warehouse Curtains Compliant

- Understanding Noise Regulations – When Is a Temporary Noise Barrier Legally Required?

- 7 Powerful Ways Industrial Curtain Walls Boost Employee Productivity

- Noise Enclosures vs. Traditional Soundproofing: Which Is Right for Your Facility?

- Steel Guard Safety Achieves SBA HUBZone Certification, Expanding Government Market Opportunities

- 5 Myths and 5 Truths about Smoke Curtains

- 7 Common Mistakes to Avoid When Setting Up Machine Guarding Fences

- Industrial Curtain Walls: 6 Reasons Why Manufacturing Facilities Must Have Them

Categories

- Accordion Fold Curtains

- Acoustic Baffles

- Agri-Shield Curtains

- Auto Body Shop Curtains

- Bio Plastics

- Draft & Smoke Curtains

- Industrial Divider Curtains

- Industrial Safety Products

- Insulated Curtain Walls

- Machine Guard Safety Fencing

- Mesh Curtain Screens

- News

- Outdoor Curtains

- PVC Strip Curtains

- Smoke & Draft Curtains

- Soundproof Noise Blocking Curtains

- Spray Paint Booth Curtains

- Tarps

- Thermal Curtains & Covers

- Uncategorized

- Warehouse Dividers

- Welding Blankets

- Welding Curtains

- Welding Screens