American Made, Iron Clad Protected - Discover the Industries Best Warranty.

Blog

7 Powerful Ways Industrial Curtain Walls Boost Employee Productivity

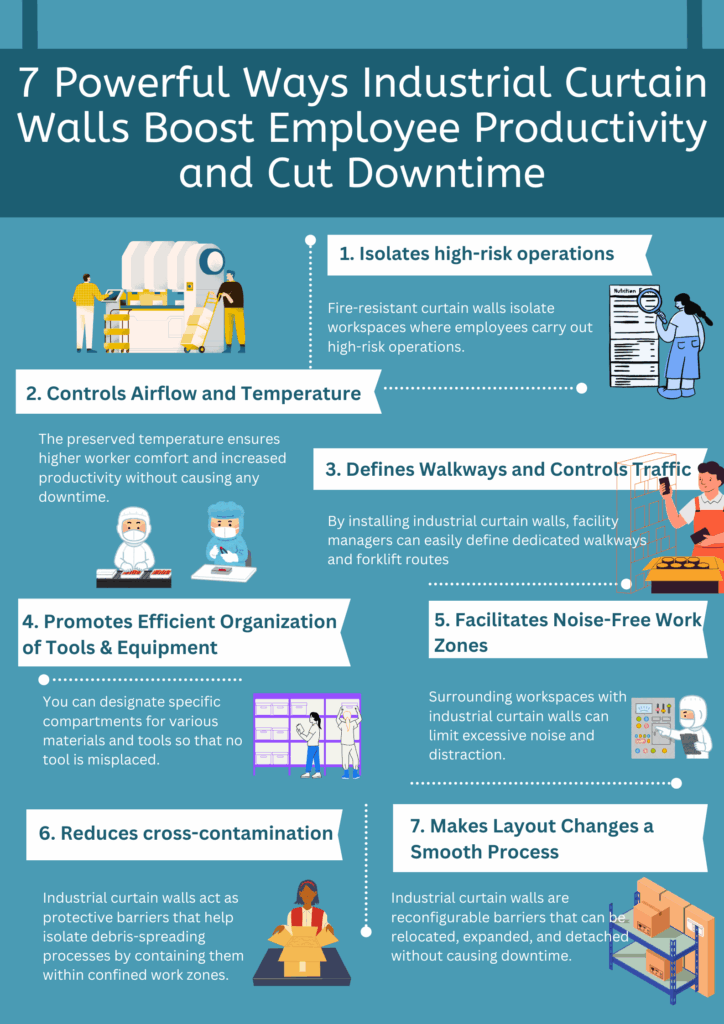

7 Powerful Ways Industrial Curtain Walls Boost Employee Productivity and Cut Downtime

In various industrial settings, employee productivity has a direct impact on business profits. Likewise, operational uptime also plays a crucial role in fulfilling large orders and massive consignments. However, facility managers often have to face downtime issues due to layout changes, equipment setup, temperature fluctuations, or area contamination. Consequently, businesses might lose potential revenue due to lost productivity.

To stay competitive, facility managers often look for smart ways to reduce downtime and increase employee productivity. Luckily, industrial curtain walls provide a strategic advantage by cutting downtime while boosting employee productivity.

If you are one such business owner or facility manager experiencing low employee productivity and constant downtime, it’s important to understand how industrial curtain walls can be a cost-cutting solution in every industrial setting.

In this post, we’ll highlight seven powerful ways in which these partitions contribute to streamlining workflow while enabling your team to work faster, smarter, and safer.

Let’s explore in detail.

1. Isolates high-risk operations

Industrial operations, including grinding, painting, battery charging, and welding often produce sparks, fire risks, and fumes. In such workspaces, accidents and fire-triggered shutdowns can interfere with the efficiency of production lines. This may result in workplace injuries (leading to increased absenteeism which directly affects their overall productivity). This is especially true in industrial environments where the entire operations are being carried out on a single, large, open floor.

Facility managers can use fire-resistant curtain walls to isolate the workspaces where employees carry out high-risk operations. These curtain walls act as partitions that prevent UV flash from spreading to other employees, thereby enhancing workforce safety. Partitioned workspaces allow uninterrupted operations without affecting employees who are working in other zones within the same floor. The sense of added safety contributes to enhancing their morale and productivity.

2. Controls Airflow and Temperature

In large-scale pharmaceutical plants and food processing facilities, it’s essential to maintain an undisturbed indoor temperature. The presence of HVAC systems isn’t sufficient, as the air can quickly escape into other work zones. This further leads to uneven cooling or heating while conducting temperature-sensitive tasks.

Fluctuations in temperature directly affect employee productivity. Since the workforce is exposed to inconsistent airflow and uncomfortable cold or heat, employees can easily experience fatigue, lack of focus, and irritability. This may result in slow performance and an increased risk of making mistakes at work. On the contrary, employees stay focused, alert, and productive in a temperature-controlled workspace.

Instead of making a large investment in new HVAC systems, installing high-quality industrial curtain walls can be a high-impact, low-cost solution. That’s because the airflow is retained within these curtain walls even at times of layout reconfiguration. The preserved temperature ensures higher worker comfort and increased productivity without causing any downtime.

3. Defines Walkways and Controls Traffic

Industrial operations in textile factories, automotive assembly plants, and manufacturing units go through various stages. But if employees are performing time-sensitive tasks in a single-floor space, the absence of walkways and excessive traffic may hinder their work. This may often happen in open areas where employees frequently face continuous traffic from forklifts and carts. Working in an unpartitioned environment leads to safety hazards, delays, and even bottlenecks – contributing to the slow completion of major tasks.

Industrial curtain walls help improve the flow of traffic by separating work zones so employees can carry out their day-to-day activities without experiencing internal traffic. By installing these curtain walls, facility managers can easily define dedicated walkways and forklift routes. This way, employees don’t have to waste time waiting for a specific path to get rid of excessive traffic. With controlled traffic around work zones, employees reach their partitioned workstations faster and work efficiently without interruptions.

4. Promotes Efficient Organization of Tools and Equipment

A cluttered workplace silently kills productivity. When equipment, tools, and materials are misplaced or scattered, employees spend a lot of time figuring out the actual location of these essentials. This delays work while slowing down the completion of tasks. It also increases the risk of errors. Businesses prone to experiencing such situations include construction sites, warehouses, packaging areas, and logistics centers.

Industrial curtain walls help combat this challenge by acting as visual and physical separators between different work zones. As a facility manager, you can use these curtain walls to designate specific compartments for various materials and tools. Such partitions enable employees to get access to critical inventory or equipment without any confusion or miscommunication. The result is greater accountability, smoother workflow, and quicker execution of urgent tasks.

5. Facilitates Focused and Noise-Free Work Zones

Excessive noise generated by welding equipment, grinders, drills, concrete mixers, and other loud machinery has a direct impact on the hearing ability and concentration levels of the workforce. Therefore, OSHA recommends that businesses incorporate hearing conservation initiatives to safeguard employees from noise stress. It’s applicable in industrial settings where noise levels are up to 85 dB or more during an eight-hour shift.

Achieving a quieter workplace is only possible if employers can facilitate employees with a calmer, noise-free workplace. Surrounding their workspaces with industrial curtain walls can limit excessive noise and distraction. This initiative also helps employees stay mentally sharp throughout their work shift, thereby leading to a healthier and productive atmosphere where employees can perform well.

Installing vinyl curtain walls with transparent design can be a wise idea. These clear-view walls allow supervisors to monitor employee performance without the need to enter their work premises or disrupt them. This way, it becomes easier to preserve their focus while maintaining oversight.

6. Reduces cross-contamination

Contamination control is a high-priority metric in various industries, including food and beverage processing, cosmetics manufacturing, electronics assembly, and medical device production. However, dust, spray, temperature swings, and fumes can affect product quality and violate hygiene and safety standards. This further leads to costly downtime and rejected products. Besides, workers are required to clean the affected work areas instead of assembling new product units, leading to wastage of productive hours and added operational loss.

Industrial curtain walls act as protective barriers that help isolate debris-spreading processes by containing them within confined work zones. That way, dust, fumes, or other contaminants cannot enter work zones where finished products are being handled and packaged.

7. Makes Layout Changes a Smooth Process

Layout reconfiguration is a common practice in various industrial settings. That’s especially true when it’s about scaling operations, adding new machinery, or shifting assembly lines. However, destroying permanent walls and rebuilding them might cause slowdowns. It also leads to an increase in operational downtime. Low production leads to missed revenue.

Constructing new walls within an existing floor space is a time-consuming process. However, industrial curtain walls enable facility managers to reshape workspaces within a couple of hours. These curtain walls are reconfigurable and flexible barriers that can be relocated, expanded, and detached without causing downtime. They also benefit businesses (such as e-commerce order fulfillment centers) that suddenly have to respond to new customer demands in peak periods.

The Takeaway

Maintaining consistent uptime while retaining employee productivity isn’t just an engineering metric. It’s a business priority. Even the smallest inefficiency can be the cause of a big loss. That’s what industrial curtain walls are for. These durable partitions provide budget-friendly, fast, and flexible solutions to various hidden obstacles your employees might be facing on a routine basis.

From isolating dangerous work zones to controlling traffic flow and providing optimum temperature, industrial curtain walls can help your team perform their best without experiencing any downtime.

Whether you’re managing a manufacturing plant, a pharmaceutical facility, or a distribution center, selecting the industrial curtain walls that suit your business requirements and floor space matters the most. Therefore, the best bet is to conduct research, inquire from professionals, and decide between choosing a ready-made industrial vinyl curtain wall or a custom-built industrial curtain wall.

Recent Posts

- The Silent Safety Hero: Why Fixed Draft Curtains Are Required in High-Rack Storage Facilities

- The Invisible Risk: How Contamination Happens Without Proper Warehouse Barriers

- Are Your Insulated Warehouse Curtains Compliant

- Understanding Noise Regulations – When Is a Temporary Noise Barrier Legally Required?

- 7 Powerful Ways Industrial Curtain Walls Boost Employee Productivity

- Noise Enclosures vs. Traditional Soundproofing: Which Is Right for Your Facility?

- Steel Guard Safety Achieves SBA HUBZone Certification, Expanding Government Market Opportunities

- 5 Myths and 5 Truths about Smoke Curtains

- 7 Common Mistakes to Avoid When Setting Up Machine Guarding Fences

- Industrial Curtain Walls: 6 Reasons Why Manufacturing Facilities Must Have Them

Categories

- Accordion Fold Curtains

- Acoustic Baffles

- Agri-Shield Curtains

- Auto Body Shop Curtains

- Bio Plastics

- Draft & Smoke Curtains

- Industrial Divider Curtains

- Industrial Safety Products

- Insulated Curtain Walls

- Machine Guard Safety Fencing

- Mesh Curtain Screens

- News

- Outdoor Curtains

- PVC Strip Curtains

- Smoke & Draft Curtains

- Soundproof Noise Blocking Curtains

- Spray Paint Booth Curtains

- Tarps

- Thermal Curtains & Covers

- Uncategorized

- Warehouse Dividers

- Welding Blankets

- Welding Curtains

- Welding Screens